FUTURE TECHNOLOGY TODAY

The HydroBreak® range is manufactured in the UK to BS5750/ISO9000 quality standards. It is completely safe and environmentally acceptable, both in use and disposal. HydroBreak® is non-toxic, non-corrosive, and has no toxic by-products – If it’s safe to use water, it’s safe to use HydroBreak®

It’s also non-volatile and non-flammable, which can bring massive savings on ventilation equipment, fire precautions and insurance premiums, and, when used in effluent treatment plant can reduce power consumption by up to 50% and greatly reduce oxygen demands.

HOW IT WORKS

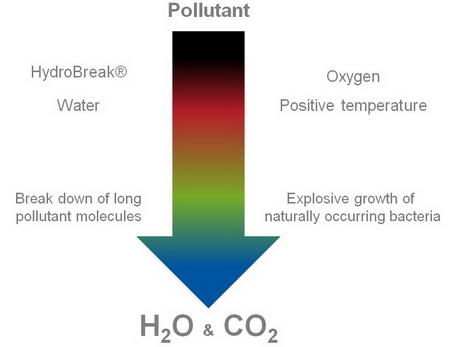

As well as releasing contaminants from polluted surfaces, HydroBreak® breaks down their long hydrocarbon molecules into shorter and more accessible chains. Its unique formulation then stimulates an ‘explosion’ of naturally occurring bacteria, which feed off the residue and convert it into H2O and CO2.

Then, with their food source gone, the bacteria are simply killed off. Unlike conventional detergents, solvents, oil dispersants or hydrocarbon-based degreasers, HydroBreak® doesn’t simply move the pollutants elsewhere, it destroys them. And since it is itself non-tainting and completely biodegradable, even when mixed with contaminants, there are no residual traces left after rinsing.

VERSATILITY

Because it can be applied safely in many ways – by hand or in floor scrubbers, steam cleaners, aqueous spray washing systems and ultrasonic units – and on a wide range of substrates, HydroBreak® can reduce the number of cleaning products required on site, simplifying ordering, storage and stock control.

HydroBreak® does not affect paints, rubbers or plastics and is compatible with most metals, including aluminium, brass, bronze, copper, iron, lead, steel and zinc. Correctly used, it can replace solvent degreasers and has none of the hazards of solvent or alkaline detergents.

Applied to oils, greases and fats, it prevents their re-forming to block drains or make floors unsafe. It can also be used in conjunction with selected bacterial strains to treat specific effluents, or on hydrocarbon spills on land or road surfaces. It won’t damage the asphalt (except HydroBreak® POWER) and it renders hydrocarbons non-flammable on application.

For finely tuned applications in effluent digestion of fats, certain hydrocarbons and free oils and greases or the bioremediation of contaminated land, HydroBreak® can be combined with specific bacterial cultures for maximum-targeted effectiveness.